Powder crushing, ball mill and sand mill applications

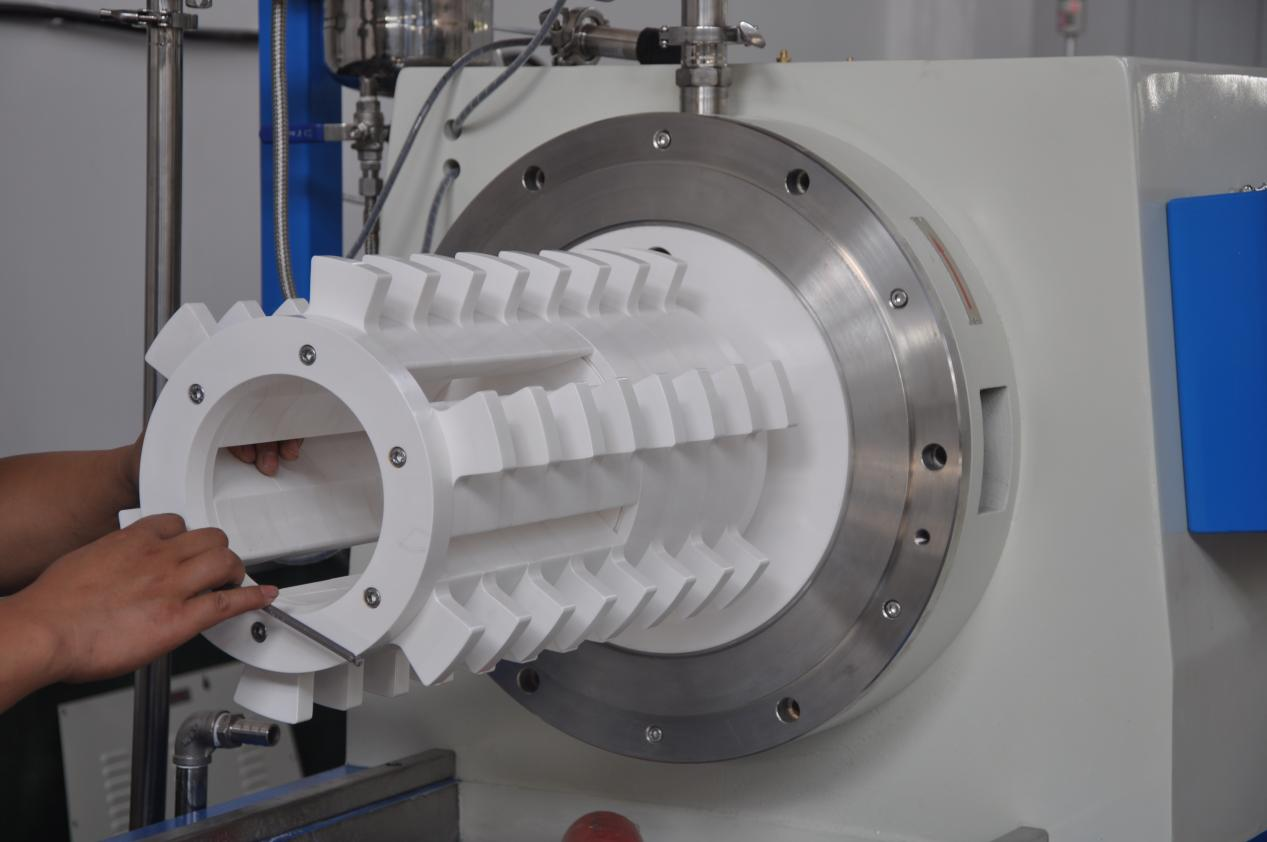

1.In sand mills, ceramic rotors and stators have high precision and high wear resistance, and can maintain stable performance under high-speed rotation and strong shear working conditions. For example, rotors and stators made of zirconia ceramics can provide precise gap control and achieve efficient grinding and dispersion, and are widely used in inks, coatings, electronic slurries and other fields.When the sand mill is working, there will be strong friction and collision between the material and the inner wall of the equipment. Using industrial ceramics as lining materials, such as silicon carbide ceramic lining, can effectively protect the equipment body, reduce wear and extend the service life of the equipment. In addition, the surface of the ceramic lining is smooth, not easy to adsorb materials, and will not release impurities such as metal ions into the materials, which can ensure the purity of the ground materials. The application of ceramic lining is very important in some industries that are sensitive to impurities, such as the production of optical glass and high-end coatings.

2.The grinding jar and grinding media in the ball mill are usually made of high-hardness ceramic materials with good wear resistance. They can resist the impact and friction with the materials during the grinding process, reduce the wear of the jar and the media, and extend the service life. Ceramic materials not only have excellent chemical stability, but are also not easy to react chemically with the materials being ground, avoiding contamination of the materials and ensuring the purity and quality of the materials after grinding. They are particularly suitable for grinding materials with high purity requirements, such as electronic materials, medicine and other fields. In addition, the thermal conductivity of ceramics is relatively low, and they have certain thermal insulation properties, which can reduce the heat transfer generated during the grinding process to a certain extent, help maintain the stability of the materials, and prevent changes in the properties of the materials due to excessively high temperatures.