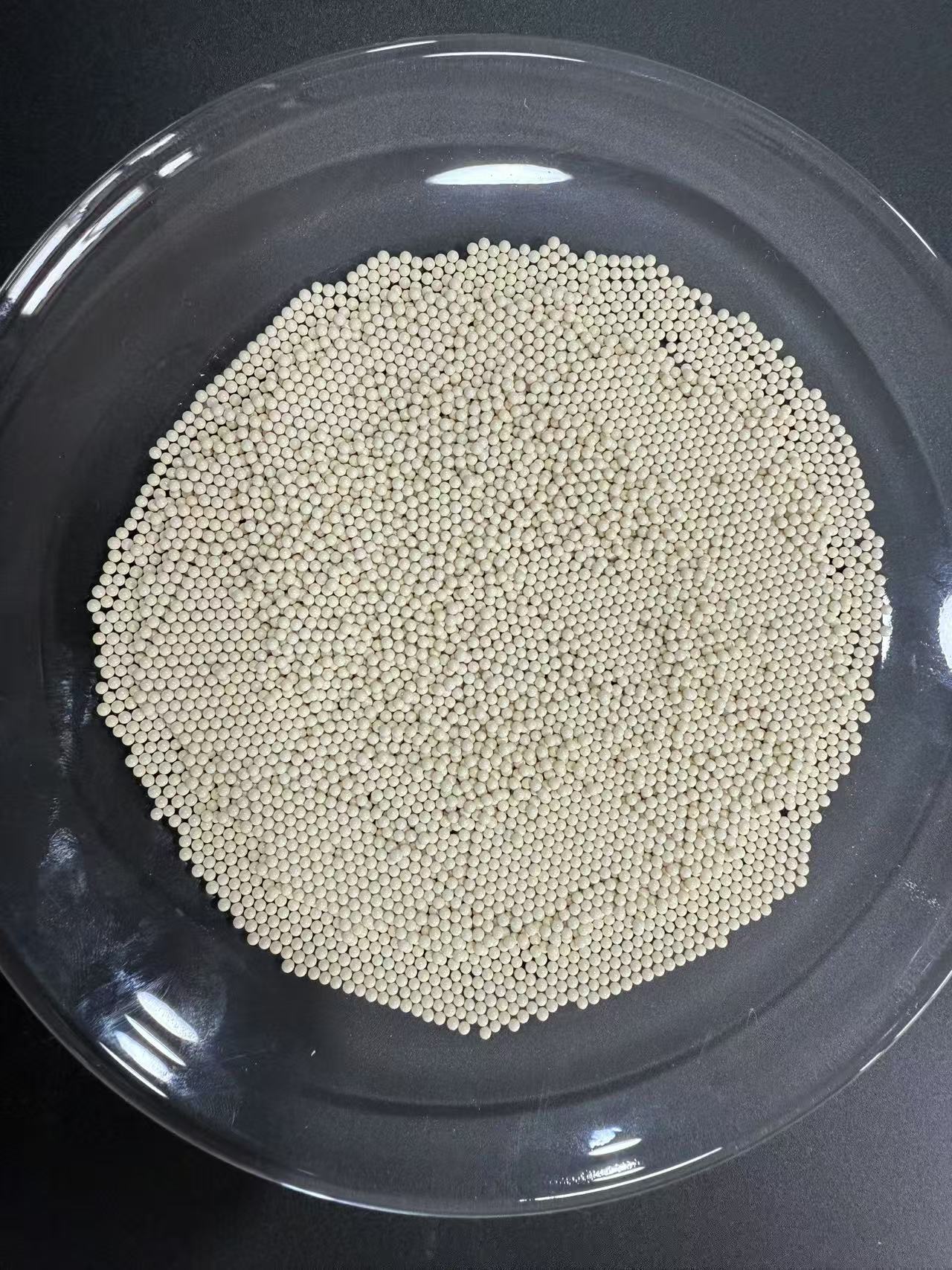

Zirconia grinding balls(beads)

STANDS AS A BEACON OF INNOVATION AND EXCELLENCE IN STRUCTURAL CERAMIC MATERIALS

Clasificación:

Ceramic Balls (Beads)

Palabra clave:

xuecheng ceramics

E-mail:

Zirconia balls, also known as "TZP" zirconium beads, are made of micron and sub-nano zirconium oxide and yttrium oxide as raw materials. They are used for ultra-fine grinding and dispersion of materials that require "zero pollution" and high viscosity and high hardness.Zirconia beads have good stability, acid and alkali corrosion resistance. They are good roundness, smooth surface, no pores, reflective luster, and are easy to clean. The micro beads have good fluidity and cause little wear on the equipment.

Items | ZrO2 content | Self- abrasion | Density | Hardness | Roundness | Size range | Crushing strength |

Unit | % | PPM/h | g/cm3 | HV | % | mm | N |

Value | 95 | ≤1 | ≥6.05 | ≥1250 | ﹥95 | 0.05~50 | ﹥900(2mm) |

Zirconia grinding balls, also referred to as TZP (tetragonal zirconia polycrystal) zirconium beads, represent a class of high-performance ceramic grinding media engineered for the most demanding industrial applications. These precision spheres are manufactured from high-purity micron and sub-nano zirconium oxide (ZrO₂) and yttrium oxide (Y₂O₃), which are sintered under stringent conditions to achieve exceptional structural integrity and performance characteristics. They are the media of choice for the ultra-fine grinding and dispersion of materials that mandate absolute purity, high viscosity, and extreme hardness, ensuring a final product completely free from contamination.

These advanced Zirconia grinding balls exhibit a suite of superior properties. They possess outstanding chemical stability, demonstrating excellent resistance to both strong acids and alkalis, which guarantees no chemical interaction with the materials being processed. Their physical attributes are equally impressive, featuring exceptional sphericity (>95% roundness), an incredibly smooth, non-porous surface with a reflective luster, and high ease of cleaning, which minimizes cross-contamination between batches. The superb fluidity of these micro beads promotes efficient grinding kinetics and contributes to significantly reduced wear on milling equipment, thereby extending machinery life and lowering maintenance costs.

The technical specifications of these Zirconia grinding balls underscore their premium quality. With a zirconia content of 95% and a remarkably low self-abrasion rate of ≤1 PPM/h, they ensure minimal product contamination and long service life. Their high density (≥6.05 g/cm³) and exceptional Vickers hardness (≥1250 HV) provide the necessary impact energy for effectively breaking down the toughest materials. Available in a wide size spectrum from 0.05 mm to 50 mm, they offer versatility for various mill types and process requirements. Furthermore, each bead boasts a high crushing strength exceeding 900 Newtons (for a 2mm bead), confirming remarkable durability and resistance to fracture even under intense operational stress.