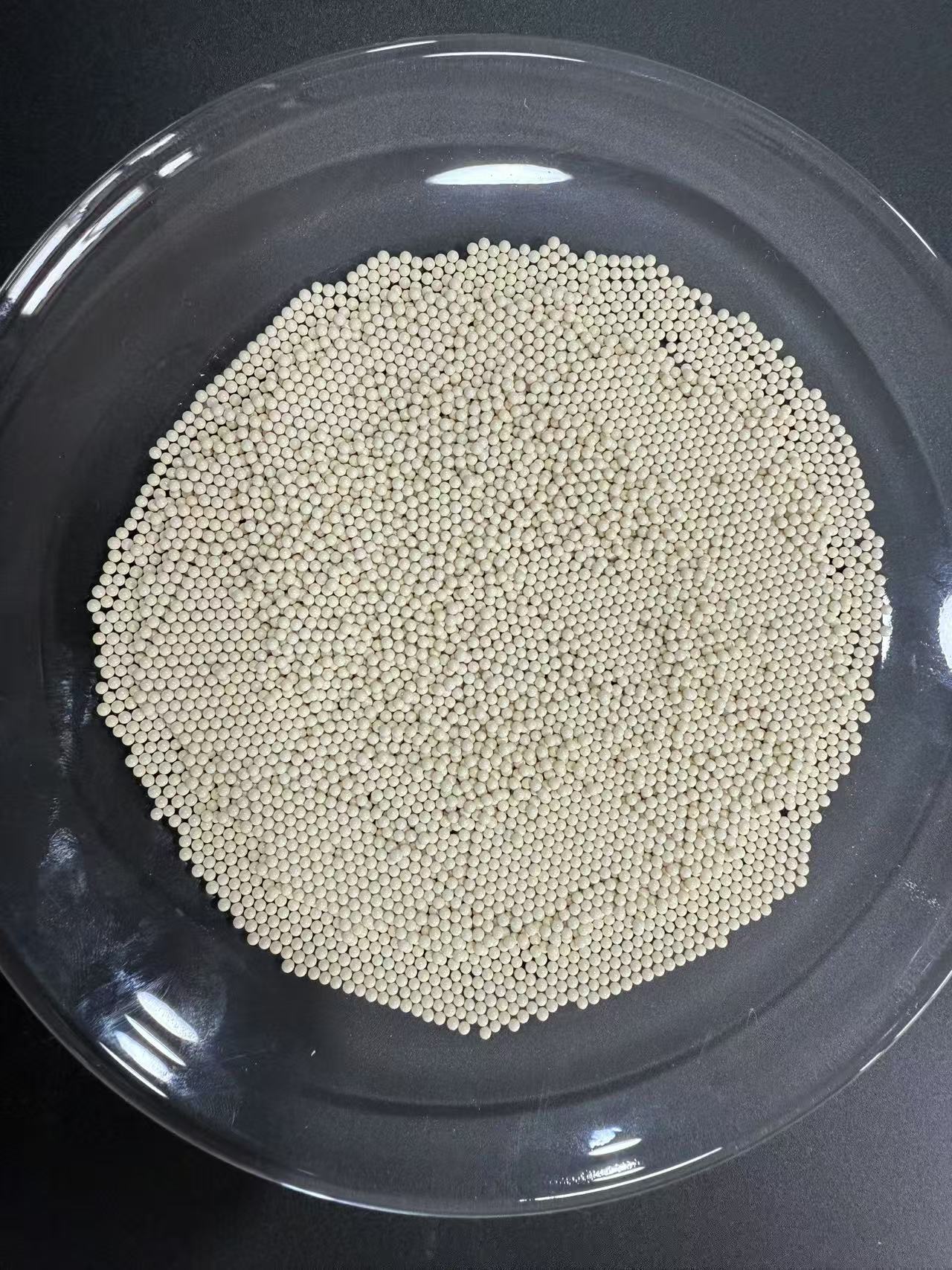

Zirconia ceramic parts for sand mill

STANDS AS A BEACON OF INNOVATION AND EXCELLENCE IN STRUCTURAL CERAMIC MATERIALS

Clasificación:

Ceramic structural parts

Palabra clave:

xuecheng ceramics

E-mail:

In the sand mill, the ceramic rotor and stator have high precision and high wear resistance, and can maintain stable performance under high-speed rotation and strong shear conditions; the ceramic lining has a smooth surface, is not easy to adsorb materials, and will not release impurities such as metal ions into the materials, thus ensuring the purity of the ground materials.

| Items | Unit | 99%A1203 | ZrO2 | Si3N4 | Sic |

| color | / | light yellow | white | black | balck |

| Water absorption | % | 0 | 0 | 0 | 0 |

| Density | g/cm3 | 3.9 | 6 | 3.2 | 3.2 |

| Flexural Strength | Mpa | 340 | 1000 | 1000 | / |

| Compressive Stragth | Mpa | 3600 | 3000 | 3600 | 2000 |

| Modulus of Elasticity | Gpa | 380 | 200 | 300 | 410 |

| Impact Resistance | Mpa.m1/2 | 5.1 | 6 | 7 | 4 |

| Vickers Hardness | HV | 1650 | 1200 | 1600 | 2000 |

| Thermal Conductivity | W/mk | 27 | <2 | 30 | 70 |

| Highest Application Temperature | ℃ | 1750 | 1050 | 1300 | 1300 |

Engineered for extreme durability and precision, our Zirconia Ceramic Parts for Sand Mill systems deliver unparalleled performance in demanding grinding and dispersion applications. These advanced components, including rotors, stators, and lining plates, are specifically designed to withstand the rigorous conditions of high-speed operation and intense mechanical shear forces. The exceptional material properties of zirconia ensure that these Zirconia Ceramic Parts for Sand Mill equipment maintain dimensional stability and operational efficiency throughout extended service periods, significantly outperforming conventional materials in both lifespan and processing consistency.

The outstanding performance of these Zirconia Ceramic Parts for Sand Mill processing stems from zirconia's unique combination of mechanical properties, including remarkable flexural strength exceeding 1000 MPa and exceptional impact resistance. This structural robustness prevents fracture and deformation under continuous operational stress, while the ultra-smooth surface finish minimizes material adhesion and facilitates easier cleaning between production batches. Unlike metal components, these ceramic parts guarantee absolute purity by completely eliminating the risk of metallic ion contamination, making them ideal for processing high-purity pharmaceuticals, premium coatings, specialty inks, and advanced electronic materials. The exceptional wear resistance of these components, demonstrated by their impressive Vickers hardness rating, dramatically reduces maintenance frequency and replacement costs while ensuring consistent particle size distribution and product quality batch after batch. For manufacturers seeking to optimize their grinding processes with reliable, contamination-free solutions, these Zirconia Ceramic Parts for Sand Mill operations represent the optimal choice for enhancing productivity and maintaining product integrity in the most challenging industrial environments.