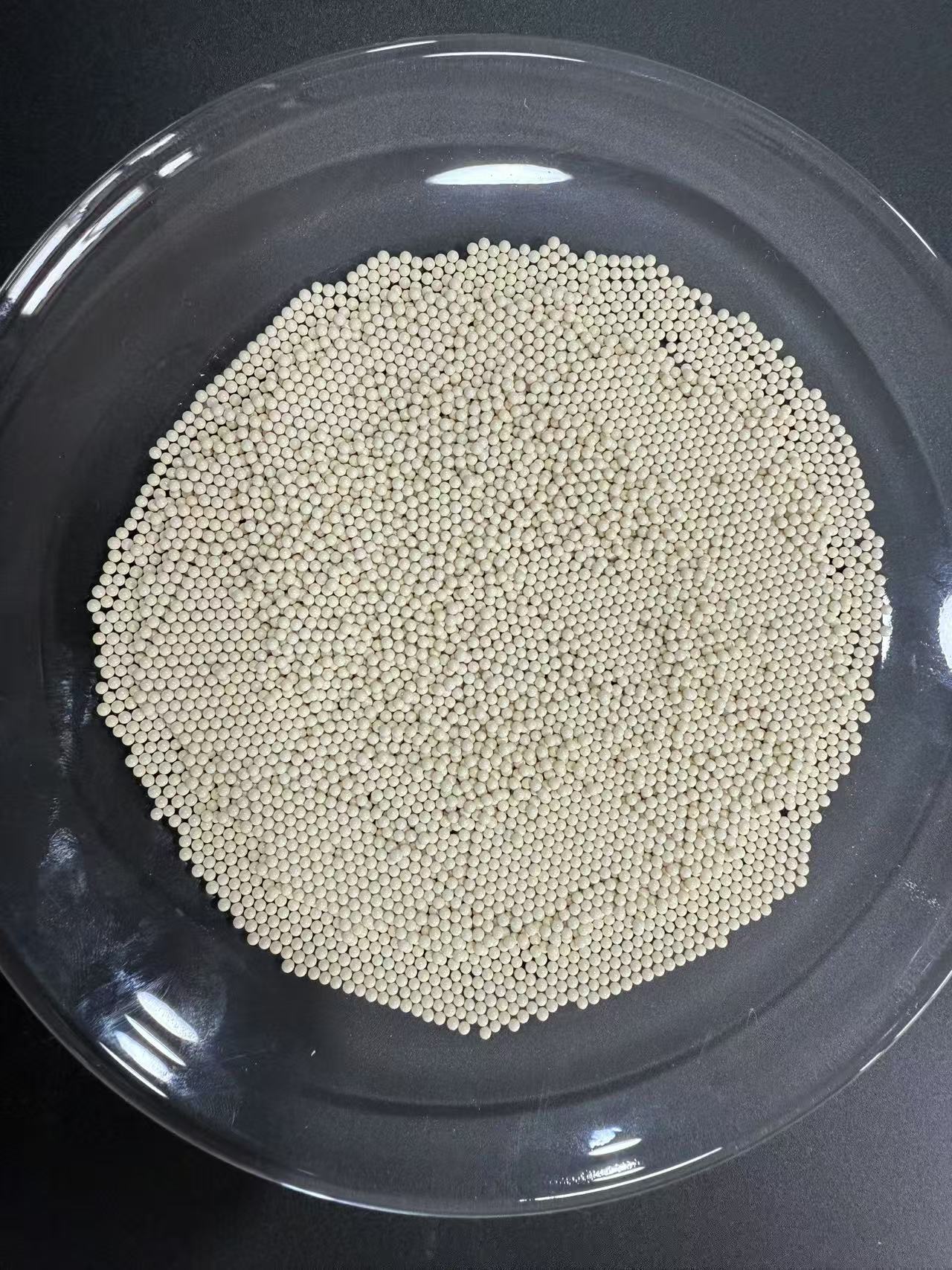

Zirconia ceramic parts for ball mill

STANDS AS A BEACON OF INNOVATION AND EXCELLENCE IN STRUCTURAL CERAMIC MATERIALS

Clasificación:

Ceramic structural parts

Palabra clave:

xuecheng ceramics

E-mail:

The grinding jar and grinding media in the ball mill are usually made of high-hardness ceramic materials with good wear resistance. They can resist the impact and friction with the materials during the grinding process, reduce the wear of the jar and the media, and extend the service life.

| Items | Unit | 99%A1203 | ZrO2 | Si3N4 | Sic |

| color | / | light yellow | white | black | balck |

| Water absorption | % | 0 | 0 | 0 | 0 |

| Density | g/cm3 | 3.9 | 6 | 3.2 | 3.2 |

| Flexural Strength | Mpa | 340 | 1000 | 1000 | / |

| Compressive Stragth | Mpa | 3600 | 3000 | 3600 | 2000 |

| Modulus of Elasticity | Gpa | 380 | 200 | 300 | 410 |

| Impact Resistance | Mpa.m1/2 | 5.1 | 6 | 7 | 4 |

| Vickers Hardness | HV | 1650 | 1200 | 1600 | 2000 |

| Thermal Conductivity | W/mk | 27 | <2 | 30 | 70 |

| Highest Application Temperature | ℃ | 1750 | 1050 | 1300 | 1300 |